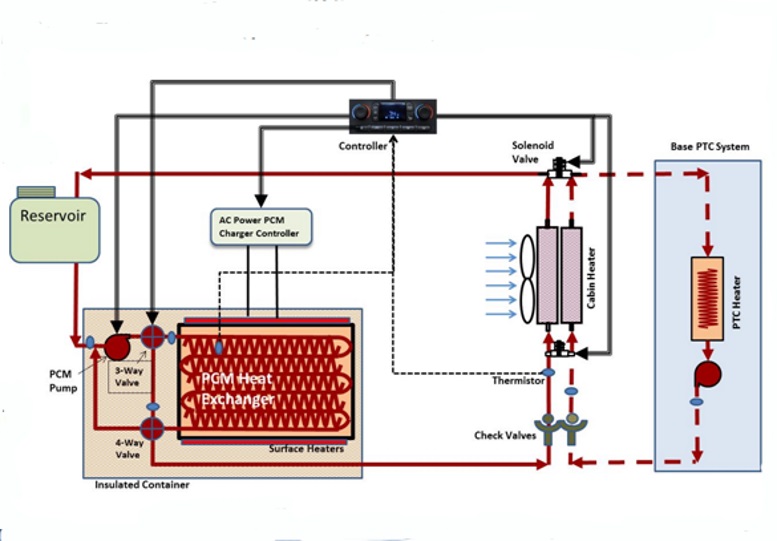

ePATHS示意图:左边主要是PCM热交换器,右边则是两步式加热器核心,车舱PTC加热器则位于背面。

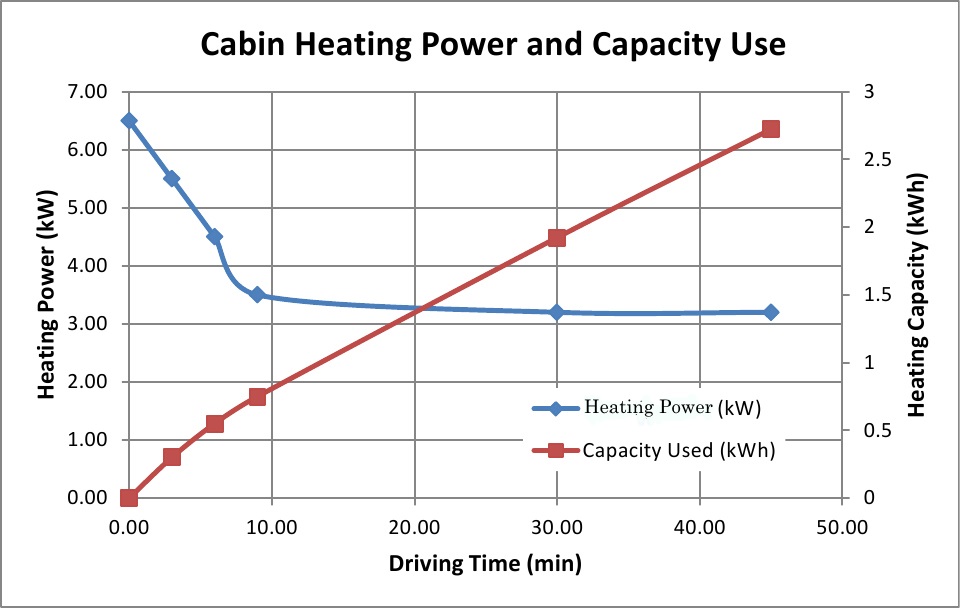

ePATHS示意图:左边主要是PCM热交换器,右边则是两步式加热器核心,车舱PTC加热器则位于背面。  热容量与电功耗数据,都可以用于衡量在特定行驶时间内,通过储热系统节省的能力。

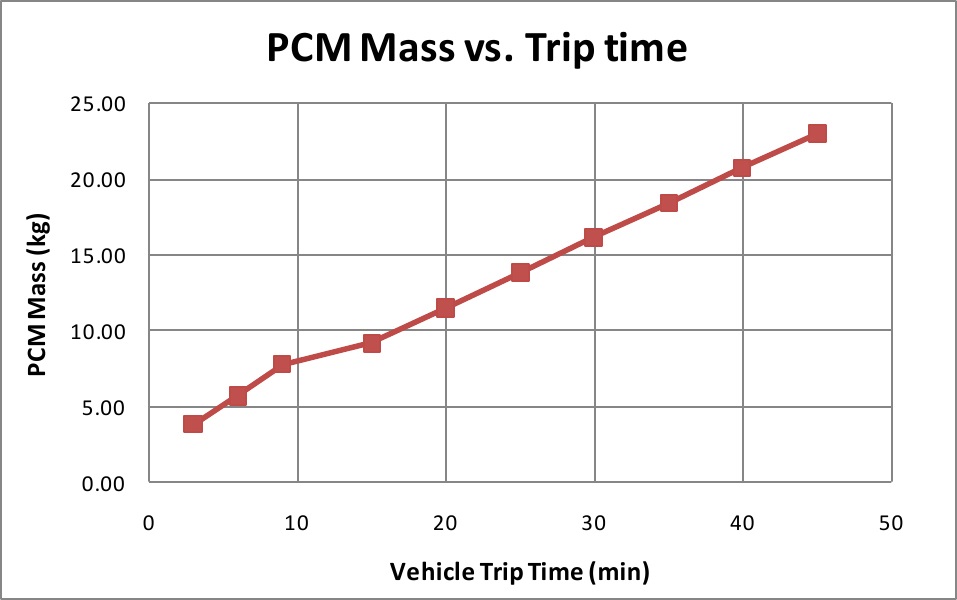

热容量与电功耗数据,都可以用于衡量在特定行驶时间内,通过储热系统节省的能力。 如图所示,所需PCM材料的质量与行程时长基本成线性增长关系。

如图所示,所需PCM材料的质量与行程时长基本成线性增长关系。

目前,热存储系统已经成为一种低成本的温控解决方案,在温暖气候下,可以在发动机怠速时维持车辆的制冷功能。最近的建模研究与实验测试显示,这种技术也同样可以作为一种平价、高效的解决方案,为电动车的车舱供暖,从而解决电动车冬季续航里程减少的问题。SAE 2016全球汽车年会期间,来自国际领先汽车与发动机制造商马勒(Mahle)公司与美国橡树岭国家实验室的研究人员展示了他们的最新研究结果。

通常来讲,电动车在寒冷天气下续航里程可能会减少60%。这是由于在天气寒冷时,车辆必须耗费大量电力为车舱供暖,而电动车动力电子元件释放的少量热量又很难收集利用。至今为止,电动车的动力电池仍然是车辆供暖系统的唯一电源,除此之外,只有一些从制冷/制热反向循环中收集的能量可供利用。

46分钟通勤驾驶所需热量

对于驾驶员而言,由于需要供暖,在寒冷的季节里驾驶电动车上班可能并不舒服,行驶距离更长时,甚至还会让他们产生里程忧虑。

现在大家都已了解到,为了保证电动车的取暖需求,而为车辆加装额外的电池,从而为车上PTC(正温度系数)或电阻加热器供电,成本实在太高了。提前预热车舱可以在一定时间内保证车内温度,加热座椅和加热方向盘等功能也能让乘客感觉更温暖。然而,根据一项盖洛普(Gallup)调查,美国人平均每天的往返通勤时间为46分钟。在这样的背景下,研发人员知道他们必须采取更多措施,缓解车主的冬日电动车“里程焦虑”,或者降低电动车在工作日的充电需求。

马勒公司与橡树岭国家实验室的研究人员表示,如果能够通过相变材料(PCM)储存充足的热量,满足车主正常通勤途中的取暖需求,则可以提高电动车在一些终年寒冷地区市场中的销量。PCM材料是指一种可以随温度变化而改变物质状态(可以由固体变为液体,或由液体变为固体),并能够在相对常温的条件下吸收或释放潜热的物质。

如今,市面上已经有一些使用内燃机的传统汽车开始利用PCM材料,维持空调在发动机怠速时的运转。通常来说,由于发动机怠速最多不会超过1分钟,因此PCM材料在这种情况下的应用成本较低,封装也很简单。驾驶员也总是可以在有必要时,重新启动发动机和空调,保持车舱内的舒适环境。内燃机车型一般将PCM材料存储在蒸发器内,可以在空调压缩机停止工作后继续提供冷空气。

在供暖方面,PCM材料一般存储在发动机盖下的热交换器舱室中,冷却液流向仪表盘后方加热器核心区域的回路内。这种PCM材料属于固体石蜡族,与辅助冷却系统中的材料很类似,但加工流程存在一定差异,最终导致该材料可以与空气和水分发生反应。因此,这种PCM材料必须小心储存,在向PCM热交换器舱室中加入这种材料之前,必须先排空其中所有的气体与水分。接着,再使用特殊设备充入PCM材料,然后密封热交换器的舱室。

研究人员评估了8种备选的PCM材料,结果发现:DPT 83的综合表现最佳,可以作为首选材料,其熔点(即相变温度)为83°C (181°F),与电动车冷却液的85°C (185°F)非常接近。因此,这种材料可以提供与PTC加热系统类似的加热器冷却温度。DPT 83是8种材料中潜热容量最高的一种,高达348J/g,远远超过之前PCM材料200J/g的潜热容量,而更高的潜热容量有助于缩小系统的封装体积。

另一种PCM材料DPT 68的性能略低于DPT 83,但同样也能满足需求,其相变温度为68ºC (154ºF),潜热容量为342 J/g。

由于空调的怠速需求,PCM材料必须能在空调-发动机运转期间快速储存热量,并为下一次怠速做好准备。但如果要满足寒冷气候下(-10°C/14°F)的车舱取暖需求,PCM系统需要面临一个更为关键的挑战,那就是如何保证系统不会在车辆长时间停在户外时,损失存储热量。为了解决这一问题,研发人员为PCM系统采用了真空绝热面板材料的轻质隔热外壳。如果一个工作日按八小时计算,预计这种PCM系统可以将热量损失控制在20%之内。

However, the engineering target is 90% heat retention and the Mahle and ORNL researchers believe that target can be met with improved construction.

然而,现阶段的目标,是将热量损失控制在10%之内。不过,虽然要求更高,但马勒公司与橡树岭国家实验室的研究人员认为,通过结构优化,10%的目标并非难以企及。

重量的代价

尽管PCM系统性能有所提升,但该系统的确也会同时增加车辆的重量。但与通过增加电池组解决取暖问题相比,PCM系统增加的重量不会增加,甚至还可能减少。研究人员最终选定的PCM系统重量约33 kg (73 lb),内含重约21 kg (46 lb)的PCM材料,外加重约12 kg (26 lb)的PCM热交换器(温度上限为120°C/248°F),可至少将车辆的续航里程延长20%。

PCM系统也能用于预热车舱,从而将车辆行驶过程中的供暖需求降至最低,也就是温度保持状态。

在制冷中,冷空气在经过仪表盘后的蒸发器时,可以使液态石蜡PCM材料凝固成固体。当车辆怠速时,空调压缩机停止工作,此时热空气将穿过处于冷却固体状态中的PCM材料,降低温度后进入车舱,实现制冷功能。由于热空气会在这个冷却过程中向PCM材料释放热量,此时PCM材料将从固态转为液态,直到空调重新开始工作,或固态PCM材料全部变为液态。

在用于车内取暖时,PCM系统的功能与车辆怠速时正好相反。目前,这种系统被命名为ePATHS,即电动PCM协助热采暖系统(electric PCM-Assisted Thermal Heating System)。ePATHS系统内含两个热交换器:PCM热交换器和仪表盘后方的车舱加热器,以及连接这两个设备之间的管道和控制阀。此外,系统还配置了用于辅助常规PTC加热器的电路。值得注意的是,这一系统中的PCM材料在常温下为固态。

该系统的工作方式是,首先车辆通过插电式供电系统进行预热,可利用电力驱动PCM热交换器中的加热元件提升车舱的温度,并同时加热PCM材料使其储存热量,变为液态。

电动泵回路

车辆运行时,车内的电动泵回路(持续运行和/或脉宽调制模式)可以将水和乙二醇的混合物送入PCM热交换器,吸收PCM材料的热量,再流入仪表盘后方的车舱加热器。内燃机车型也会将经过发动机加热的冷却液送入车舱供暖装置,采用的原理与电动车类似。

这种解决方案可以将现有电动车在寒冷天气下的续航里程提高20%,轻松超过原定目标。如果进入PCM系统的外部空气有70%温度在-10°C/14°F之间,则系统能够运行40分钟。

整个PCM加热系统的功率输出相当于3.3kW·h。不过,PCM系统还可以利用一些其他热量:当PCM材料已经释放了绝大部分潜热时,系统内还会残留一些热量,原因是这部分热量的温度无法达到60°C (140°F),这是PCM系统发挥加热功能的温度需求。

即使如此,这部分热量还有其他可以发挥作用的地方,系统的双加热器核心就可能从中受益。此时, PCM热交换器将可以继续循环从核心前方流入的经过加热的乙二醇/水混合物,对流入的气流进行预热,这个过程可以将PCM系统的工作时间延长10分钟,也就是说此时PCM系统总共可以运行50分钟。接着,当经过加热后的乙二醇/水混合物流入核心后方区域时,车辆的PTC加热器将被激活,开始进行供暖。

作者:Paul Weissler

来源:SAE《汽车工程》杂志

翻译:SAE上海办公室

2016 SAE Congress: Thermal storage is solution to EV winter range loss

Thermal storage, now coming into use as a low-cost method to maintain A/C cooling during idle stops in warm weather, has been identified by modeling studies and laboratory tests as also offering an inexpensive and effective solution for heating the cabin of electric vehicles. The study results were presented by researchers from Mahle and the Oak Ridge National Laboratory during the 2016SAE World Congress.

Electric vehicles typically lose up to 60% of their operating range during cold weather operation due to the power required to heat the passenger compartment, while the small amount of heat rejected by EV power electronics would be difficult to collect efficiently. To now, the vehicle's traction batteries have been the only power source for conventional heating, with some added efficiency from reverse-cycling the A/C into heat pump operation.

Heat needed for 46-min commute

For EV drivers, the winter-heating demand can make a routine commute uncomfortable and even dreadful over longer distances.

Adding enough extra battery capacity for a commute-length source of conventional warmth from PTC (positive temperature coefficient) or resistance heaters has been deemed too costly. Preheating the cabin provides a short period of warmth, and features such as heated seats and steering wheel can improve occupants' perception of warmth. However, the length of the average U.S. round-trip commute is 46 minutes, according to a Gallup survey. Engineers recognize that more has to be done to make the winter commute free of range anxiety – or the need to recharge while the car is parked during the workday.

Sufficient thermal storage in Phase Change Material (PCM) for a complete commute could improve the EV's prospects as year-round transportation in cold-winter markets, according to the Mahle and ORNL experts. PCM is a class of materials that go through a phase change (solid-to-liquid or vice versa) while absorbing or releasing a large amount of latent heat at a relatively constant temperature.

The use of PCM to maintain A/C cooling during an idle stop, already available for some internal-combustion vehicles, is a relatively low-cost, easily packaged answer, as the total required cooling interval typically is less than one minute. And if necessary, the engine and A/C system can be restarted to maintain comfort. For IC vehicles, the PCM is held in storage areas built into the evaporator, chilling the airflow when the compressor has been stopped.

For heating, the PCM is stored in chambers in an underhood heat exchanger that is in a loop with coolant flow to the under-dash heater core. The material is in the paraffin wax family - similar to that used for supplemental cooling, but it's processed differently and as a result would react with air and moisture. Therefore, the material must be stored carefully and prior to installation in the PCM Heat Exchanger (Hx) chamber, the chamber must be evacuated to remove any air and moisture. Using special equipment, the Hx then is charged with PCM and the chamber is sealed.

The first-choice PCM, designated DPT 83, has a melting point (phase change temperature) of 83°C (181°F), sufficiently close to the EV coolant temperature specification of 85°C (185°F). This should enable it to provide heater coolant temperature approximately equivalent to what a PTC (Positive Temperature Coefficient) heater system would deliver. Latent heat capacity is 348 joules/gram, highest of eight PCMs evaluated and well above the 200 J/g of older PCMs, which helps minimize package size.

Slightly lower in performance but also potentially suitable is DPT 68, which has a phase change temperature of 68ºC (154ºF) and a latent heat rating of 342 J/g.

With A/C idle stop, it is important for the PCM to recharge quickly from the A/C-engine restart and be ready for the next idle stop. But for cabin heating, the more critical demand is ensuring remaining PCM heat storage isn't lost through the workday in cold weather (-10°C/14°F) while the EV is parked outdoors. Through an eight-hour workday, the PCM heat exchanger is projected to retain 80% of the remaining latent heat by employing a lightweight insulation package made with vacuum-insulated panels.

However, the engineering target is 90% heat retention and the Mahle and ORNL researchers believe that target can be met with improved construction.

Weight penalty

The improved PCM notwithstanding, the PCM system does add weight. But (depending on the lithium-ion battery pack used) the overall mass increase is no more, or even less, than increasing the size of the battery pack. The researchers decided on a total package of 33 kg (73 lb), including 21 kg (46 lb) of PCM plus 12 kg/ 26 lb for the PCM heat exchanger (charged to 120°C/248°F) to provide at least 20% range extension.

The PCM system also assumes a pre-heated cabin, which reduces the vehicle-in-operation demand to steady-state heating.

For A/C operation, cold air passing through the under-dashboard evaporator freezes the liquid wax-type PCM to form a cold solid. During idle stop, the compressor stops and warm air passes over the solidified PCM to provide cooled cabin airflow. As the air gives up heat to the PCM, the PCM changes from solid to liquid until the A/C restarts or the cold storage is exhausted.

When the PCM is used for heating the cabin, it functions opposite of the idle-stop process. This configuration was named ePATHS—electric PCM-Assisted Thermal Heating System. It consists of two heat exchangers: the PCM Hx and the under-dash passenger compartment heater, with tubing and control valves to connect them. In addition, there is an electrical loop that adds the conventional PTC heater. The PCM is a solid at ambient temperature.

The pre-charge starts with the EV plug-in system that uses electricity to charge the EV battery pack and, via electric heating elements inside the PCM Hx, also heats the PCM to a liquid (while also operating the PTC heaters to pre-warm the cabin).

Electric pump circuit

In vehicle operation, an electric pump circuit (operating continuously and/or in pulse-width-modulated mode) runs a water-glycol mixture through the PCM Hx, absorbing heat from the molten PCM and flowing to the under-dash heater. This is somewhat similar to the IC-engine setup that flows engine-heated coolant to the cabin heater.

The proposed system is projected to comfortably exceed the targeted 20% increase in EV range. Using 70% outside air at -10°C/14°F, it would operate in PCM-only mode for 40 min.

Total PCM heating is equivalent to 3.3 kW·h. However, there's more heat available: when most of the PCM latent heat is exhausted, there still is some residual heat, even if at about 60°C (140°F) it is at too low a temperature for full PCM heating function.

That's energy worth using, and a dual-heater core is projected to take advantage. The PCM Hx continues to circulate the heated glycol/water mixture through the forward section of the core to preheat the incoming airflow, adding an additional 10 minutes to PCM heating, for a total of 50 min. The PTC heater is activated to complete the heating of the glycol/water solution as it flows through the rear section of the core.

Author: Paul Weissler

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Paul Weissler

- 行业:汽车

- 主题:环境燃料和能源噪声、振动与声振粗糙度质量、可靠性与耐久性工程设计与造型电气电子与航空电子测试与检验